Environmental Know-How: Covering Existing Stockpiles

Open air stockpiles are a common sight around the globe, and stockpile operators are seeking ways to cover their piles from rain, fluctuating temperatures and wind. These natural occurrences can deplete inventories and affect the chemical composition of raw materials.

But more importantly, manufacturers across various sectors are focused on the environmental impact of uncovered piles. Dust emissions and contaminated runoff can affect surrounding communities, vegetation and wildlife. With new environmental regulations across the world, covering existing stockpiles is or will be a requirement. Eco-friendly initiatives include the design and installation of long span storage solutions that help stockpile operators tread more softly around Mother Nature.

The goal is to seamlessly connect bulk storage and materials handling solutions with mining, cement, fertilizer and power generation operations. Of course, manufacturers want to cover their stockpiles, if only covering existing stockpiles was easy. Most of them were not designed to be covered and the mere thought of doing it sounds impossible without downtime and extremely high costs.

Challenges in Covering Existing Stockpiles

Conventional building systems have limitations and simply cannot accommodate covering large spans on uneven terrain:

• Brutal slopes

• Typhoon winds

• Hazardous and combustible raw material

• Punishing snow loads

• Corrosive marine environments

As a stop gap measure, stockyard operators have tried storing raw materials in silos, which are small, expensive and often impractical. A long term solution was needed, and Geometrica answered the call with an all-terrain application designed specifically for industries that handle large volume bulk materials.

Benefits of Geometrica's Bulk Storage Domes

Roel Castano, Vice President of Geometrica, addressed storage and environmental concerns as a speaker at the Cemtech Conference in Bangkok in June 2015. He noted the obstacles faced by global stockpile operators and offered an alternative to the limitations of traditional structures. Geometrica's revolutionary patented all-terrain building system offers economical and efficient bulk storage options while lowering lifetime maintenance costs through excellent long span design, cladding options and safety accessories.

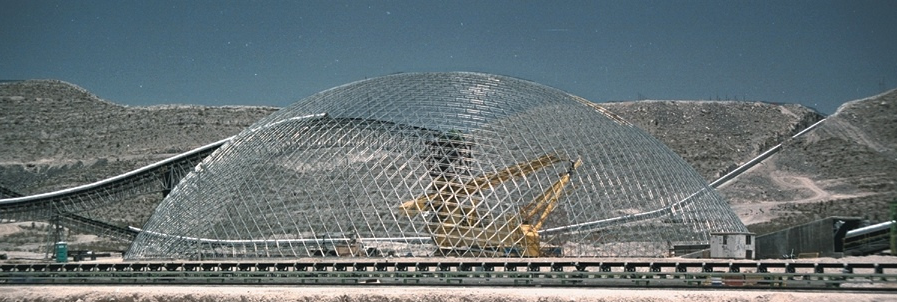

Castano noted that Freedome® technology has taken long span storage to, literally, new breadths and heights. Freedomes — Geometrica's trademark for free-style domes — provide all the advantages of circular domes with a non-circular plan. All tube members are different and may have lamella, kiewitt or lace insurface patterns and single or double structural layers. Big foundations for these large span roofs is not required, even at spans up to 300m. This allows versatility and flexible design options for irregular piles and stockyards.

The Geometrica system includes a node, or linear thread aluminum connector, that joins galvanized steel or aluminum tubes. The ductile behavior develops 130% of the steel tube’s rated yield strength and transfers bending. It features human-scale modules, dense packing volume, and easy installation requiring minimal use of rigging equipment with no field welding required.

Only Geometrica's non-traditional structures provide the strength and span necessary to enclose stockyards of any size in any location. The column-free space is unique in that it allows the transfer of moments across the joint. Notably, the barrier-free interior allows the maximum use of space, while allowing the free-flow of traffic, personnel, vehicles, conveyers and other equipment — even while the pile is in operation. This equates to zero downtime or loss of productivity.

Environmentally Positive Impact

Hundreds of uncovered stockpiles still exist worldwide and can benefit from Freedome® technology. Now mines, plants and factories can opt for a new vanguard in long span design in any terrain or climate.

Geometrica's environmentally sustainable enclosed domes protect stockyards of minerals, limestone, clay, clinker, coal, marl, wood chips, fertilizers and sulfur from outside elements, and ensure the landscape is protected from particulates and groundwater leeching — a win/win situation for manufacturers and the communities they serve.

Flexible Freestyle Long Span Examples

Consider the heart-shaped copper storage Freedome at Planta Cerrillos in Atacama, Chile. The main area encompassed more than 5000 m2 in a shape that was irregular after several expansions over the years. There was no way to fit a conventional circular dome on this site. A Freedome® was the ultimate solution.

Existing equipment and buildings forced the shape: crushers and sifter equipment had to be enclosed, while a hopper had to remain outside. The supporting structure had to bridge existing buildings. Spans were 90m in the principal directions — a whimsically-shaped three sided structure with rounded corners and a dimple in one of the sides.

No equipment modifications were required. When the dome was approved for construction, all elements varied from each other, meaning this project was truly a custom architectural achievement. Thanks to precision pre-fabrication, it was installed by local labor who had no problems following the simple procedures required to build it.

Other benefits of Covering Existing Stockpiles

Geometrica's proprietary software controls design, fabrication, packaging and installation. Structures are bar coded and containerized in convenient two ton crates and delivered anywhere in the world.

Domes can be built from the perimeter up with simultaneous installation of dome and stacker/reclaimer equipment. No secondary structure is required for cladding. Local labor can be used for installation over a light foundation.

About Geometrica

Geometrica is an award winning international firm serving industrial and environmental protection markets worldwide. The company believes a culture of safety begins within an organization and extends to its products and services, and explicitly values ethics, safety, quality, learning and continuous improvement. Worker safety is a priority — a value advanced by certifications in health, safety, management and manufacturing processes.

Geometrica implemented a quality management system (QMS) through an internal company wiki, which helped achieve safety certification status in a minimal time.

ISO 9001:2008 Certified quality management system

OHSAS 18001 Certified health and safety management system

ISO 3834-2 Welding Quality Certification

EN 1090 construction products standard certification - New CE marking for design and manufacturing of components and structures made of steel and aluminum for the execution of structures.

As a 2nd generation dome builder founded on gridshell technology that has been in development for 50 years, the company leads the market in freestyle, long span and light weight domes and space frames with projects in more than 30 countries.

The question is, "What can Geometrica build for you?" To learn more about our bulk storage solutions, please fill the inquiry form.